Introduction:

Understanding the concept of Foundation in Construction:

The foundation of a building or civil structure is the part of the structure that is directly in contact with the surrounding soil. It is responsible for safely transferring loads from the building to the soil. Generally, a foundation can be divided into two categories: a shallow foundation and a deep foundation. In a shallow foundation, the load is transferred to a layer present at a shallow depth, while in a deep foundation, it is transferred further down to a layer that is present at a deeper depth. For tall buildings, such as skyscrapers, or buildings constructed on extremely weak soil, a deep foundation is necessary. Additionally, if the constructed building is intended to expand vertically in the future, a deep foundation should be proposed.

Constructing a foundation necessitates the excavation of trenches into the soil until a solid layer is reached. This layer is then filled with concrete to create a stronger base foundation. The trenches are reinforced with a reinforcement cage to further strengthen the foundation. Proposed steel rods projected outwards serve as the bones of the foundation, which must be connected to the substructure. After the foundation is packed correctly, the building can begin to be constructed. The foundation can be constructed using a variety of materials, from concrete to steel, as well as stones and bricks.

The materials and type of foundation chosen for the structure must be based on the design load and the soil type. Additionally, the design must take into account the environmental effects of construction. For instance, excavation and piling works for a deep foundation may lead to adverse impacts on the surrounding soil and the structural foundation, which can sometimes cause settlement issues in the vicinity. These effects must be thoroughly studied and managed prior to the commencement of the construction. Finally, any waste material generated must be disposed of in an appropriate manner.

The foundation must be constructed in such a way that it is capable of resisting the external attack of hazardous substances. The foundation of each structure must be designed to ensure that the underlying soil does not suffer from shear failure, that the settlement caused during the initial service load is contained or within the permissible bearing pressure, which is the pressure the soil is able to withstand without failure.

Foundation and its Purpose:

- The stability of a structure is largely dependent on its foundation. The stronger the foundation, the more stable the structure.

- The appropriate design and construction of the foundations ensure a suitable surface for the substructure to develop at the appropriate elevation and over a stable foundation.

- The specially designed foundation facilitates the prevention of lateral movement of the supporting material.

- A well-maintained foundation transfers the load onto the bed surface in a consistent manner. This consistent transfer helps to prevent the building from settling unevenly, which is known as differential settlement.

- The purpose of the foundation is to distribute the load across the entire base area of the structure and then onto the soil beneath. The load transferred onto the soil should fall within the permissible soil bearing capacity.

Foundation in Construction and its Functions:

Based on the purpose of the foundation, the functions of the foundation are listed below:

- To provide overall lateral support for the structure.

- For the construction of substructure, foundations serve as the function of providing a level surface.

- The distribution of the load is carried out evenly.

- To be within the safe bearing capacity of the soil, the load intensity is reduced.

- The movement of the soil is resisted and prevented.

- Issues such as scouring and undermining are resolved by the construction of the foundation.

Good Foundation and Requirements:

- The design and construction of the foundation shall be designed and constructed in such a way as to not only support the structure but also to transfer the dead weight and the imposed load to the soil. The transfer shall be carried out without causing any settlement that could lead to any stability problems for the structure.

- In order to prevent differential settlements, it is necessary to have a fixed foundation for the foundation. The problems of differential settlements are more acute in areas where the imposed loads are not homogeneous.

- This is largely due to the issue of thermal shrinkage and swelling. Therefore, depending on the soil and the area, a deeper foundation is recommended to protect against any form of harm or distress.

- The chosen site for the foundation must be situated in an area that will not be subject to or affected by any future works or elements.

Pile Foundation:

A pile foundation, also known as a deep foundation, is a thin column or long cylinder of concrete or steel that can be cast in-situ, driven at the location where the structure is being supported, and moved to the required depth by either end-bearing friction or skin friction. Pile foundations are used as structural members to move the load of a structure to a specific depth within a deep foundation to carry the load that may be vertical, lateral, or lateral and vertical.

In this blog post, let us explore the various types of pile foundations and their utilities in construction.

Introduction to Pile Foundation:

Pile foundations are nothing but piles which are dug into the soil. The foundation takes the load of the building to the bearing soil with a better load carrying capacity. These pile foundations come very handy in regions or areas with an unstable upper soil which is not a good sign for large buildings. Hence, pile foundations come into the picture in such circumstances.

When Pile Foundation is Preferred:

- When the distribution is uneven and the superstructure has a heavy weight, pile foundation is highly preferred.

- Pile foundation is required when the topsoil has a weak bearing capacity or has a weak upper layer soil.

- Pile foundation is necessary in areas where the construction activities are located near the water bodies as there is a danger of water filtration.

- Pile foundation is required when subjected to uplifting forces.

- When the surface area is prone to soil erosion.

Pile Foundations and their role in supporting structures:

Pile foundations are a type of deep foundation used in civil engineering and construction to support structures, especially in situations where shallow foundations, such as spread footings, are inadequate. Pile foundations are essentially long, slender columns or pillars made of various materials, typically steel, concrete, or timber, which are driven or drilled into the ground. They play a crucial role in supporting structures for several reasons:

- Load Transfer:

Pile foundations are used when the soil near the surface is unable to support the loads imposed by the structure. Piles transfer the structural loads (vertical and horizontal) to deeper, more competent soil or rock layers, which can effectively support the weight of the structure.

- Settlement Control:

Pile foundations help control and minimise settlement, which is the downward movement of the building due to the compressibility of the soil. By reaching stable soil or bedrock at greater depths, piles reduce the potential for uneven or excessive settlement.

- Stability in soft or loose soils:

In areas with soft, loose, or compressible soils, such as clay or silt, pile foundations provide a stable base for structures. The deep insertion of piles ensures that the building remains stable and does not sink into the ground.

- Resistance to lateral loads:

Piles can also provide resistance to horizontal or lateral loads, such as wind, seismic forces, or the thrust of retaining walls. Pile foundations help prevent tilting, sliding, or overturning of the structure in response to these forces.

- Bridge Foundations:

Pile foundations are commonly used in bridge construction, where they support bridge piers and abutments. The deep penetration of piles helps transfer the heavy loads of the bridge and traffic to stable soil or rock layers beneath the riverbed or ground surface.

- Waterproofing:

In waterfront or marine construction, piles are often used to support structures like docks, piers, and offshore platforms. They can be designed to withstand the corrosive effects of water and provide stable support.

- Environmental Considerations:

In some cases, pile foundations are used to minimise the environmental impact of a structure. By avoiding extensive excavation and disturbance of the ground, pile foundations can reduce disruption to sensitive ecosystems.

In short, pile foundations are essential in civil engineering and construction because they ensure the stability, safety, and longevity of structures, particularly in challenging soil conditions or when facing heavy loads and lateral forces. They offer a reliable solution to prevent excessive settlement and provide support in situations where shallow foundations are inadequate.

Types of Pile foundations:

Pile foundations can be classified into following categories as listed below:

1. End-Bearing Piles

End-bearing piles are also known as point-bearing pile or tip-bearing pile is a type of pile foundation designed to transfer the structural loads from a building or structure to a load-bearing, non-compressible stratum, typically a hard layer of soil or rock, located deep below the ground surface. The term "end-bearing" comes from the fact that the primary function of these piles is to bear the load at their lower or "end" point, where they are in direct contact with the firm, load-bearing stratum. Here are some key characteristics and details about end-bearing piles:

- Load Transfer:

End-bearing piles are installed by being driven or drilled deep into the ground until they reach a strong and stable layer of soil or rock. The load from the structure is primarily transferred to this bearing layer at the pile's tip.

- Material Selection:

End-bearing piles are typically made of materials that can penetrate the soil or rock effectively, such as reinforced concrete, steel, or timber. The choice of material depends on factors like the load to be supported and the specific site conditions.

- Depth of Penetration:

The depth to which end-bearing piles are driven or installed can vary depending on site-specific factors, including the depth of the load-bearing stratum and the magnitude of the structural loads. The deeper the pile is driven, the more load it can support.

- Use in Various Soil Conditions:

End-bearing piles are especially effective in areas where the soil near the surface is not suitable for supporting the structure due to its low bearing capacity. These piles can provide a stable foundation in a wide range of soil conditions, including loose or compressible soils.

- Common Applications:

End-bearing piles are often used in bridge construction, high-rise buildings, transmission towers, and any other structure where the depth to the load-bearing stratum is significant. They are especially suitable for situations where shallow foundations would be impractical.

- Design Considerations:

The design of end-bearing piles involves analysing the site's geotechnical conditions, calculating the structural loads to be supported, and selecting the appropriate pile type, size, and material. The design must ensure that the pile can safely transfer the loads to the bearing stratum.

- Load Testing:

Load tests are often conducted on end-bearing piles to confirm their load-carrying capacity and verify that they meet the design requirements. Load tests help ensure the stability and safety of the foundation.

End-Bearing piles are an important type of pile foundation used in civil engineering to provide a stable and reliable means of transferring structural loads to load-bearing strata, which are typically located deep beneath the ground surface. Their use is essential in areas with challenging soil conditions where the load-bearing capacity of the soil near the surface is insufficient to support the structure.

End-Bearing Piles and their Utilities:

End-bearing piles, also known as point-bearing piles, play a crucial role in construction by providing a stable foundation for structures in situations where the soil near the surface is unsuitable for supporting the loads. These piles are designed to transfer the structural loads to a load-bearing stratum, typically a hard layer of soil or rock deep below the ground surface. Here's how end-bearing piles are used in construction:

- High-Rise Buildings - End-bearing piles are commonly used in the construction of tall buildings where the loads can be substantial. In urban areas with limited space, it is often necessary to build upwards. These piles provide a solid foundation, ensuring the building remains stable, even in soft or compressible soils.

- Bridge Foundations: Piles are frequently used in bridge construction to support bridge piers and abutments. In many cases, the bearing stratum is located deep below riverbeds or the ground surface. End-bearing piles help transfer the significant loads of the bridge and traffic to stable soil or rock layers.

- Transmission Towers: Transmission towers that carry power lines or telecommunication equipment are typically constructed in various types of terrain, including remote or hilly areas. End-bearing piles are often used to anchor the tower's foundations securely to the bedrock below.

- Large Industrial Structures: Industrial facilities like refineries, chemical plants, and manufacturing plants require sturdy foundations, especially if the loads they carry are heavy or unevenly distributed. End-bearing piles are essential in such situations to ensure the structural stability of these facilities.

- Retaining Walls: In construction projects that involve retaining walls, such as in highway construction, piles may be used to provide lateral support and resist the soil pressures exerted by the retained earth. These piles can help prevent the wall from tilting or collapsing.

- Offshore and Marine Structures: In marine construction, such as the building of docks, piers, and offshore platforms, end-bearing piles are used to anchor the structures to the seabed or lakebed. These piles are designed to withstand the corrosive effects of water and provide stable support for the structures.

- Environmental Considerations: In environmentally sensitive areas, where extensive excavation and ground disturbance could have a significant impact, end-bearing piles are used to minimise the disruption to the natural surroundings. This approach helps protect ecosystems while providing a stable foundation for the structure.

- Urban Redevelopment: In urban areas with existing infrastructure, end-bearing piles may be used to support new construction projects when shallow foundations would be impractical due to the presence of utilities, underground structures, or weak soil layers.

End-bearing piles are essential for ensuring the stability, safety, and longevity of a wide range of structures, making them a critical component in the field of civil engineering and construction.

End-Bearing Piles and Advantages:

- Load-Bearing Capacity : End-bearing piles are designed to bear and transfer heavy vertical loads, making them suitable for structures with substantial weight or dynamic loads, such as high-rise buildings, bridges, and industrial facilities.

- Stability in Challenging Soils: They are particularly valuable in areas with challenging soil conditions, such as loose, compressible, or expansive soils, where shallow foundations may be inadequate. The piles reach down to stable strata, ensuring the stability of the structure.

- Settlement Control: End-bearing piles help control and minimise settlement by providing support from a load-bearing stratum, which prevents excessive or differential settling of the structure. This is crucial for ensuring the longevity of the building.

- Resistance to Lateral Loads: These piles can also resist lateral loads, such as wind forces and seismic loads. Their deep penetration into stable strata prevents the structure from tilting, sliding, or overturning in response to these forces.

- Versatility: End-bearing piles can be used in various construction projects, from buildings and bridges to transmission towers, retaining walls, and offshore structures. Their versatility makes them suitable for a wide range of applications.

- Environmental Benefits: In sensitive environmental areas, end-bearing piles can minimise ground disturbance compared to traditional excavation methods, making them an environmentally friendly option for construction projects.

- Reduced Footprint: End-bearing piles require a relatively small footprint, which is advantageous in urban areas where space is limited, or in projects that need to avoid impacting nearby structures or utilities.

- Load Testing: End-bearing piles are typically subjected to load tests to verify their load-carrying capacity. This testing ensures that the foundation system meets design requirements and provides a high level of safety and reliability.

- Durability: Piles are constructed from materials such as concrete, steel, or timber, which can be chosen based on the specific project requirements. These materials are durable and resistant to environmental factors, ensuring a long-lasting foundation.

- Cost-Effective: In some cases, end-bearing piles can be more cost-effective than alternative foundation methods, as they reduce the need for extensive site preparation and excavation.

End-Bearing Piles and Disadvantages:

While end-bearing piles have their advantages, they also come with certain drawbacks which are listed below:

- Limited capacity in soft soils: End-bearing piles are most effective in areas where there is a firm and stable load-bearing stratum at a reasonable depth. In very soft or loose soils, the end-bearing capacity may be limited, making them less suitable for certain sites.

- Pile material limitations: The choice of material for end-bearing piles is crucial. If the material is not strong enough, it can lead to issues such as bending or breaking of the pile during driving or under load. Common materials for end-bearing piles include concrete, steel, and timber.

- Driveability concerns: Driving end-bearing piles can be challenging, especially in rocky or hard soil conditions. The equipment used for pile driving must be capable of penetrating the soil or rock to reach the load-bearing layer, which can be costly and time-consuming.

- Noise and vibrations: The pile-driving process for end-bearing piles can generate significant noise and vibrations, which can be disruptive to nearby structures, the environment, and even impact the integrity of adjacent structures.

- Environmental impact: Pile driving can have adverse effects on the surrounding environment, including potential damage to aquatic ecosystems if the construction site is near a waterbody. It can also cause soil disturbance and compaction in the vicinity of the piles.

- Cost: Installing end-bearing piles can be more expensive than other foundation methods, particularly in areas where the load-bearing layer is deep or difficult to reach. The cost of materials, equipment, and skilled labour can be substantial.

- Pile spacing and layout: The design and spacing of end-bearing piles are critical to their effectiveness. Improper spacing or layout can result in differential settlements or uneven load distribution, leading to structural issues.

- Corrosion (for steel piles): If steel piles are used, they are susceptible to corrosion in certain environments, which can reduce their load-bearing capacity and longevity. Corrosion protection measures must be employed in such cases.

- Maintenance and repair: Over a period of time, end-bearing piles may require maintenance or repair, especially in areas with changing soil conditions or if they are subjected to increased loads. This can be costly and disruptive.

- Limited adaptability: Once end-bearing piles are installed, it can be challenging to modify or adapt the foundation system to accommodate design changes or unforeseen circumstances, compared to more flexible foundation solutions like shallow foundations.

2. Friction Piles

Friction piles, also known as skin friction piles or cohesion piles, are a type of deep foundation used in construction to support structures by transferring loads from the building to the surrounding soil through the frictional resistance between the pile and the soil. Unlike end-bearing piles, which rely on the bearing capacity of a firm stratum or bedrock beneath the soil, friction piles depend primarily on the frictional forces along the length of the pile and, to a lesser extent, the end-bearing capacity.

Here is how friction piles work in the construction process:

- Pile Material: Friction piles are typically made of materials like concrete, steel, or timber. The pile is driven or installed deep into the soil until it reaches a stable layer or bedrock. Unlike end-bearing piles, the load-bearing capacity of friction piles is not reliant on the bottom tip's bearing capacity.

- Frictional Resistance: The primary mechanism of load transfer in friction piles is the frictional resistance between the sides of the pile and the surrounding soil. As the pile is driven or installed into the ground, it displaces soil, creating a zone of compacted soil or disturbed soil around the pile shaft.

- Shaft Capacity: The load-carrying capacity of the friction pile is determined by the frictional resistance along the entire length of the pile shaft. This capacity depends on factors such as the pile's surface area, the type of soil, and the degree of soil compaction or adhesion to the pile.

- Structural Load Transfer: The structural loads from the building or structure are transmitted to the pile through the pile cap, which distributes the loads to the piles. The piles then transfer these loads to the surrounding soil through frictional resistance. The goal is to ensure that the frictional resistance can support the required load without excessive settlement.

Friction Pile and their Utilities:

Friction piles are a type of deep foundation used in construction to transfer structural loads to the surrounding soil through the frictional resistance between the pile and the soil. They are typically used in situations where the load-bearing capacity of the soil near the surface is inadequate to support the structural loads. Friction piles have various utilities in construction, including:

- Soft or Loose Soil Conditions: Friction piles are particularly useful in areas with soft, loose, or unconsolidated soil that cannot support heavy structural loads. By driving friction piles deep into the ground, they can reach more stable soil layers or bedrock, providing the necessary load-bearing capacity.

- Urban Environments: In densely populated urban areas where space is limited and adjacent structures or sensitive structures are present, the use of friction piles can minimise the noise and vibrations associated with pile driving. They are a practical choice for building foundations in such settings.

- Bridge and Overpass Foundations: Friction piles are commonly used in the construction of bridges, overpasses, and other transportation infrastructure. These structures often require deep foundations to reach load-bearing strata beneath potentially weak or compressible soils.

- Retaining Walls: When constructing retaining walls, friction piles can be used to provide lateral support to the wall by anchoring them deep into the soil. This helps resist the horizontal forces exerted by the retained soil or backfill.

- High-Rise Structures: Tall buildings often require deep foundations due to their substantial weight and the need for stability. Friction piles can be used to support the massive loads of high-rise buildings and distribute the loads to the more competent soil or bedrock below.

- Industrial Constructions: In the construction of industrial facilities such as factories, warehouses, and power plants, friction piles are commonly employed to support heavy machinery and equipment, as well as the structure itself.

- Offshore Structures: For structures like oil platforms or offshore wind turbines, friction piles are used to anchor these structures to the seabed. They are driven into the seabed to provide stability and prevent the structure from drifting.

- Differential Settlement Mitigation: In areas where there are varying soil conditions, friction piles can be employed to minimise differential settlement. This helps ensure that the entire structure settles uniformly, reducing the risk of damage.

- Lateral Load Resistance: Friction piles can also be used to resist lateral loads, such as strong winds like hurricanes, cyclones or seismic forces like earthquakes, by relying on the frictional resistance between the pile shaft and the surrounding soil. This is common in regions with high wind or seismic activity.

- Repair and Retrofitting: Friction piles can be used for the repair or retrofitting of existing structures. By adding friction piles beneath an existing foundation, the load-bearing capacity can be increased, providing a cost-effective way to enhance the structure's stability.

Friction Piles and their Advantages:

Friction Piles offer several advantages in various construction scenarios that are highlighted below:

- Versatility: Friction piles can be used in a wide range of soil conditions, making them a versatile choice for construction projects. They are suitable for both cohesive (clay) and non-cohesive (sandy) soils, as well as mixed soil profiles.

- Minimal Environmental Impact: Compared to other deep foundation methods like driven piles, friction piles generate fewer vibrations and noise during installation, making them a more environmentally friendly choice, especially in urban or sensitive areas.

- Space Efficiency: In congested urban environments where space is limited, friction piles are advantageous because they don't require large equipment and can be installed in close proximity to existing structures.

- Cost-Effectiveness: In some situations, friction piles can be more cost-effective than other deep foundation options, especially when the load-bearing stratum is not too deep and is accessible through a friction-based approach.

- Reduced Settlement: Properly designed and installed friction piles help distribute the structural loads evenly, which can reduce the potential for differential settlement. This is important for maintaining the stability and integrity of a structure.

- Adaptability: Friction piles are flexible and can be used in combination with other foundation methods, such as end-bearing piles or raft foundations, to address specific site conditions and design requirements.

- Load Capacity: The load-carrying capacity of friction piles can be substantial when they are installed to the appropriate depth and in suitable soil conditions. They can effectively support heavy structural loads.

- Minimised Disturbance: Since friction piles rely on frictional resistance rather than disturbance to the soil structure, they often have less impact on the surrounding soil properties, which can be crucial in certain construction contexts.

- Ease of Inspection: Friction piles are relatively easy to inspect during installation, making it possible to assess the quality of the pile's installation and adherence to design specifications.

- Distributed Load Transfer: Friction piles distribute the structural loads evenly along the entire length of the pile shaft, which can enhance the overall stability of the foundation.

- Longevity: When properly designed and constructed, friction piles can have a long service life, providing lasting support for structures.

Friction Piles and their Demerits:

- Uncertain Load-Bearing Capacity: The load-bearing capacity of friction piles is highly dependent on the frictional resistance between the pile and the surrounding soil. This resistance can be challenging to predict accurately, and it may vary with changes in soil properties, moisture content, and time. Therefore, there can be uncertainty in the ultimate load-carrying capacity of friction piles.

- Settlement and Compression: Over time, friction piles may experience settlement or compression, particularly if they are subjected to long-term or cyclic loading. This can result in uneven settlement, which may affect the structure's stability and integrity.

- Length Limitations: The effectiveness of friction piles is limited by the depth to which they can be installed into the soil. In certain situations where a very deep, stable load-bearing stratum is required, end-bearing piles or other deep foundation methods may be more suitable.

- Complex Design: Designing friction piles can be more complex than designing other types of piles because it involves estimating the frictional resistance, considering the soil conditions, and accounting for the potential for differential settlement.

- Soil Variability: Soil conditions can vary significantly within a construction site. In some cases, the pile may encounter layers of soil with varying properties, which can make it challenging to determine the precise load-bearing capacity.

- Corrosion (for steel piles): If steel piles are used as friction piles, they are susceptible to corrosion in certain environments. Corrosion can reduce the load-carrying capacity and longevity of the piles and require maintenance or protection measures.

- Difficult Soil Types: In certain soil types, such as loose sands, where cohesion is minimal, developing adequate frictional resistance can be difficult. Additional measures, such as using larger-diameter piles or soil improvement techniques, may be necessary.

- Construction Tolerances: Achieving the desired level of frictional resistance during pile installation can be challenging. If the piles are not installed properly and reach the intended depth, their load-bearing capacity can be compromised.

- Installation Challenges: Friction pile installation can be more time-consuming than that of other foundation types. It may also require specialised equipment and skilled labour. This can result in increased construction costs.

- Maintenance and Repair: Like other foundation types, friction piles may require maintenance or repair over their lifespan, especially if the site conditions change or the piles are subjected to increased loads.

- Environmental Impact: Although friction piles generate less noise and vibrations during installation compared to other deep foundation methods, they can still have an environmental impact, particularly if the construction site is near environmentally sensitive areas or water bodies.

3. Composite Piles

Composite piles are a type of deep foundation used in civil engineering and construction that combine two or more different materials to optimise their load-bearing capacity and performance. They are designed to leverage the unique strengths of each component to overcome the limitations of individual materials. Composite piles are typically used in situations where the soil conditions or structural requirements are complex and demand a specialised foundation solution. The two most common types of composite piles are:

- Concrete and Steel Composite Piles: These piles combine the compressive strength of concrete with the tensile strength and corrosion resistance of steel. Typically, the pile consists of a concrete-filled steel shell. The steel shell provides the required structural strength, while the concrete core adds to the overall stiffness and load-bearing capacity. These piles are commonly used in areas with corrosive soil conditions or when the pile needs to resist bending moments.

- Concrete and Timber Composite Piles: These piles combine the advantages of concrete and timber. The concrete section at the top of the pile provides resistance to compression loads, while the timber section, typically at the bottom, offers good resistance to lateral loads and bending moments. These piles are often used in waterfront structures and other applications where timber's ability to withstand moisture and corrosion is valuable.

Composite Piles and their Utilities:

Composite piles, which combine two or more different materials to optimise load-bearing capacity and performance, have a wide range of utilities in civil engineering and construction projects. These versatile foundation elements are particularly useful in situations where soil conditions, environmental factors, or structural requirements are complex and demand a specialised foundation solution. Here are some of the common utilities of composite piles:

- Marine and Coastal Structures: Composite piles, especially those combining concrete and steel or concrete and timber, are commonly used in the construction of marine and coastal structures. These include docks, piers, jetties, seawalls, and other waterfront infrastructure. Composite piles are well-suited to resist the harsh, corrosive conditions found in saltwater environments.

- Bridges and Overpasses: Composite piles can be employed in the construction of bridge foundations and overpasses, where they provide the required load-bearing capacity to support heavy transportation infrastructure. They are particularly useful in areas with challenging soil conditions or seismic activity.

- Industrial Facilities: Composite piles are often used in the construction of industrial facilities, such as factories, refineries, and power plants, where they support heavy machinery and equipment. The composite design can enhance the piles' ability to withstand varying loads and conditions.

- Wharves and Docks: In addition to marine structures, composite piles are used in the construction of wharves and docks. The combination of materials in composite piles allows them to resist both vertical and lateral loads, making them suitable for these applications.

- Retaining Walls: Composite piles can be used to support retaining walls, especially when there is a need for a combination of vertical and lateral load-bearing capacity. The piles help anchor the retaining wall and provide stability.

- Moisture-Prone Environments: Composite piles are a preferred choice in areas with high groundwater levels, where the piles are partially submerged in moisture-prone soil. The use of timber in composite piles can provide resistance to decay and moisture-related issues.

- Environmental Considerations: In projects that prioritise sustainability and minimising the environmental impact, composite piles can be designed with materials that have a lower ecological footprint. For example, sustainable timber can be used in the composite to reduce the project's carbon footprint.

- Customised Load-Bearing Capacity: Composite piles can be tailored to meet specific load-bearing requirements. The combination of materials and the arrangement of components can be adjusted to suit the project's unique demands.

- Cost-Effective Solutions: In certain scenarios, composite piles can provide a cost-effective solution, particularly when compared to fully steel or fully concrete piles, as they optimise the use of materials to achieve the desired performance.

- Seismic Zones: Composite piles can be useful in areas with seismic activity, as the combination of materials can enhance the piles' resistance to lateral forces and bending moments associated with earthquakes.

- Remediation and Retrofitting: In cases where existing structures or foundations require retrofitting or remediation to meet new design standards or increased loads, composite piles can be used to strengthen the foundation while minimising disruptions to the existing structure.

Composite Piles and their Merits:

- High Load Capacity: Composite piles can bear a substantial load, making them suitable for supporting large and heavy structures. The combination of materials like concrete and steel provides excellent load-bearing capacity.

- Versatility: Composite piles can be customised to suit specific project requirements. Engineers can adjust the type and proportion of materials used to optimise performance for different soil conditions and load requirements.

- Corrosion Resistance: The use of steel and concrete in composite piles helps protect against corrosion, ensuring the longevity of the foundation element even in aggressive environments.

- Ductility: Composite piles tend to have good ductility, which means they can deform without sudden failure, making them more resilient against dynamic loads, such as those from earthquakes, any external factors, or heavy machinery.

- Environmental Benefits: Some composite pile materials, like fibreglass or carbon fibre, have a lower environmental impact compared to traditional materials, such as timber or steel. This can be an advantage in terms of sustainability and reducing the carbon footprint of a construction project.

- Ease of Installation: Composite piles are often easier and quicker to install compared to other deep foundation options, like driven piles or drilled shafts. This can lead to cost savings on construction projects.

- Improved Control and Quality: The manufacturing process for composite piles allows for better quality control and consistency, which can result in more reliable foundation elements.

- Reduced Maintenance: Composite piles require minimal maintenance over their lifetime, as they are less susceptible to issues like rot (in the case of wood piles) or corrosion (in the case of steel piles).

- Longevity: When designed and installed correctly, composite piles can have a long service life, providing stable support for a structure for many years.

- Cost-Effectiveness: In some cases, composite piles can be a cost-effective solution, especially when considering the reduced need for maintenance and the extended service life.

Composite Piles and their Demerits:

Composite piles can have certain demerits depending on the specific project requirements and conditions. Some of these drawbacks include:

- Cost: Composite piles can be more expensive to manufacture and install compared to conventional piles made of a single material. The use of multiple materials and additional connections or components can increase the overall cost of the foundation system.

- Complexity: The design and installation of composite piles can be more complex than single-material piles. Engineers and contractors need to carefully plan and execute the installation, taking into account the behaviour of each material and their interactions.

- Corrosion: If steel components are part of the composite pile, they may be susceptible to corrosion, especially in environments with high moisture or aggressive soil conditions. Corrosion can lead to long-term degradation and maintenance issues.

- Compatibility: Ensuring that different materials within the composite pile are compatible and will not experience adverse reactions over time can be a challenge. Incompatible materials may lead to deterioration or reduced load-bearing capacity.

- Maintenance: Depending on the materials used and environmental conditions, composite piles may require more maintenance over their lifespan compared to traditional piles. This can add to the long-term cost of the foundation system.

- Environmental Impact: The manufacturing and disposal of composite pile components may have a larger environmental footprint compared to simpler foundation systems. This is a concern in sustainable construction and environmental considerations.

- Quality Control: The quality control and inspection of composite piles can be more challenging due to the variety of materials and components involved. Ensuring that all components are properly connected and integrated can be a demanding task.

4. Sheet Piles

Sheet piles are a type of structural element used in civil engineering and construction to provide temporary or permanent retaining walls in various applications, primarily for excavations, cofferdams, and waterfront structures. They are typically made of steel, but can also be constructed from concrete, wood, or composite materials. Sheet piles are interlocked to form a continuous wall, and they are driven into the ground or soil to create a barrier that resists lateral pressures and retains earth or water. Here are some key aspects of sheet piles in civil engineering;

Types of Sheet Piles:

- Steel Sheet Piles: These are the most common and versatile type of sheet piles. They come in various shapes and sizes, such as U-shaped, Z-shaped, or straight web profiles, and can be used in various soil conditions.

- Concrete Sheet Piles: Made of reinforced concrete, these sheet piles are durable and suitable for long-term applications.

- Wooden Sheet Piles: These are made of timber and are used in less demanding applications due to their limited durability and load-bearing capacity.

- Composite Sheet Piles: These are made from a combination of materials, such as fibreglass, and are used in specific conditions that require resistance to corrosion or other environmental factors.

Sheet Piles and their Utilities:

Sheet piles are an important construction element used in civil engineering and construction projects for various utilities. They serve as versatile and efficient tools for addressing a wide range of engineering challenges. Here are some of the utilities and applications of sheet piles:

- Retaining Walls - One of the primary utilities of sheet piles is retaining walls. They are used to retain soil or other materials and prevent them from collapsing into excavations, roadways, or structures.

- Cofferdams - Sheet piles are widely used to create cofferdams, which are temporary enclosures in water bodies. Cofferdams are used to keep water out of specific construction areas, allowing for work on bridge foundations, building foundations, and repair projects.

- Bulkheads & Seawalls - In waterfront applications, sheet piles are used to create bulkheads and seawalls. These structures protect against erosion, stabilise shorelines, control water levels, and provide support for docks and other waterfront structures.

- Cut-off Walls - Sheet piles can be used as cut-off walls to isolate or contain contaminated soils. They prevent the lateral migration of pollutants and protect groundwater quality.

- Flood Control & Levees - In flood-prone areas, sheet piles are used to construct levees and flood protection systems. They help contain rising water levels and protect communities and infrastructure from flooding.

- Bridge Abutments & Wing Walls - Sheet piles are used in the construction of bridge abutments and wing walls to support and retain the soil or embankment surrounding the bridge.

- Trench Shoring - Sheet piles are employed to provide shoring support in trenches during pipeline, utility, or sewer construction, ensuring worker safety and soil stability.

- Port & Harbour Infrastructure - Sheet piles are used in port and harbour construction to create docks, quays, and other structures that facilitate shipping and port operations.

- Underground Parking Garages - Sheet piles are most often used as the foundation for various structures, both temporarily and as a permanent solution, depending on the project requirements.

- Environmental Containment - In environmental remediation projects, sheet piles are used to create containment walls around hazardous waste sites, preventing the spread of contaminants.

Sheet Piles and Advantages:

- Effective Retaining Structures: Sheet piles are primarily used as retaining walls. They excel at retaining soil or other materials, preventing them from collapsing into excavations, roadways, or structures. This ability is crucial in creating safe and stable working environments.

- Cofferdams for Water Control: Sheet piles are commonly used to create cofferdams in water bodies. Cofferdams keep water out of specific construction areas, enabling work on bridge foundations, building foundations, and repair projects. They provide a dry workspace in wet environments.

- Quick Installation: Sheet piles are relatively quick to install, making them suitable for time-sensitive projects. Their installation speed can lead to cost savings and a faster project timeline.

- Versatility: Sheet piles can be used in various soil conditions, ranging from cohesive soils to granular soils. They are adaptable to different construction scenarios, offering flexibility in design and application.

- Space Efficiency: Sheet piles are particularly effective in tight spaces and urban construction, where space constraints can be a challenge. Their vertical installation minimises the footprint of the retaining structure, saving valuable space.

- Reusability: Sheet piles can often be extracted and reused in other projects. This reusability reduces construction costs and minimises environmental impact, making them a sustainable option.

- Temporary or Permanent Use: Sheet piles can serve as either temporary or permanent retaining structures, depending on the project requirements. They are suitable for both short-term and long-term applications.

- Support in Trench Shoring: Sheet piles provide shoring support in trenches during pipeline, utility, or sewer construction, ensuring worker safety and soil stability. They prevent cave-ins and protect workers.

- Design Flexibility: Sheet piles come in various shapes and sizes, including U-shaped, Z-shaped, or straight web profiles. This diversity in design options allows engineers to select the most suitable type for a specific project's requirements.

- Environmental Containment: In environmental remediation projects, sheet piles are used to create containment walls around hazardous waste sites, preventing the spread of contaminants and protecting the surrounding environment.

- Cost-Effective Solution: The speed of installation, reusability, and suitability for various applications can make sheet piles a cost-effective solution for many construction projects.

- Durability: Steel sheet piles, in particular, are known for their durability and resistance to corrosion. They can withstand harsh environmental conditions and have a long service life.

Sheet Piles and Disadvantages:

While sheet piles offer numerous advantages in civil engineering and construction projects, they also come with some disadvantages and limitations that need to be considered when choosing them as a construction solution. Here are some of the common disadvantages of sheet piles:

- Corrosion for Steel Sheet Piles: Steel sheet piles are susceptible to corrosion, especially in aggressive soil and marine environments. This corrosion can lead to reduced structural integrity and may require ongoing maintenance or protective coatings to prolong their lifespan.

- Limited Depth of Penetration: The depth to which sheet piles can be driven may be limited in certain soil conditions, such as very dense or hard layers. This limitation can impact their effectiveness in retaining soil or water in deep excavations.

- Lateral Load Capacity: Sheet piles may have a limited ability to withstand very high lateral pressures, depending on the soil type and the material used. In some cases, additional support or anchoring may be required to prevent wall deflection or failure.

- Noise and Vibration during Installation: The process of driving sheet piles into the ground can generate significant noise and vibrations, which may be disruptive to nearby residents and sensitive structures. Noise and vibration control measures may be necessary.

- Environmental Impact: The manufacturing and disposal of sheet piles, especially steel sheet piles, can have a significant environmental footprint. Consideration should be given to the environmental impact, particularly in projects with sustainability goals.

- Limited Aesthetics: Sheet piles are functional and not known for their aesthetic appeal. In some urban or waterfront projects, their appearance may be considered unattractive, and aesthetic considerations may limit their use.

- Cost of Removal: If sheet piles are installed as temporary structures, their removal can be expensive and time-consuming, especially if they have been driven to significant depths or have become embedded in soil or sediment.

- Interference with Utilities: During installation, sheet piles can interfere with underground utilities, such as pipelines and cables, and can cause damage or the need for relocations.

- Quality Control: Ensuring proper alignment and interlocking of sheet pile sections during installation can be challenging and may require rigorous quality control measures to prevent gaps or misalignment in the wall.

- Project-Specific Design: The design of sheet pile walls must be tailored to the specific project requirements and soil conditions. This can make the design process more complex and site-specific.

- Local Regulations and Permits: Local regulations and permits may restrict or govern the use of sheet piles in certain areas, especially in environmentally sensitive or densely populated regions.

Despite these disadvantages, sheet piles remain a valuable construction solution in many scenarios. Proper engineering and design, along with appropriate material selection, can help mitigate some of these drawbacks. It's essential to carefully assess the project's requirements, site conditions, and potential challenges before deciding to use sheet piles in civil engineering projects.

5. Screw Piles

Screw piles, also known as helical piles, helical piers, or screw anchors, are a type of deep foundation system used in civil engineering and construction. These piles are designed for stabilising structures, supporting heavy loads, and transferring them to more stable soil or bedrock. Screw piles consist of helical-shaped steel plates, also known as helices or flights, which are attached to a central steel shaft. Here's an overview of screw piles and their applications in civil engineering:

Structure & Components:

- Screw piles consist of a central steel shaft with one or more helical plates or flights (typically two to four) attached to it.

- The helical plates are designed with a spiral shape, similar to a screw, which allows them to be rotated into the ground.

Installation Process:

- Screw piles are installed using specialised machinery that applies torque to the pile, causing it to rotate and screw into the soil.

- The rotation of the pile advances it into the ground, creating a stable foundation as the helical plates displace and compact the soil.

Screw Piles and their Utilities:

Here are some of the utilities and applications of screw piles:

- Support for Foundation -

One of the primary utilities of screw piles is to provide support for building foundations. They are particularly useful in areas with poor soil conditions or sites where traditional shallow foundations are not practical. Screw piles offer a stable and reliable foundation for a wide range of structures, including residential, commercial, and industrial buildings.

- Boardwalks & Elevated Walkways -

Screw piles are commonly used in the construction of boardwalks, elevated walkways, and pedestrian bridges in environmentally sensitive areas like wetlands, shorelines, or conservation areas. They provide a secure and environmentally friendly foundation solution without disturbing the natural surroundings.

- Utility Poles & Signage -

Screw piles are used to support utility poles, road signs, billboards, and outdoor signage. They offer a stable and long-lasting foundation for these structures, making them suitable for various infrastructure and public safety applications.

- Temporary Structures -

Screw piles can be employed for temporary structures such as construction site trailers, event stages, fencing, and temporary shelters. They allow for quick and cost-effective installation, making them a practical choice for short-term projects.

- Solar Panel Arrays -

Screw piles are used to anchor solar panel arrays, especially in solar farm installations. The stability and adjustability of screw piles make them ideal for supporting the weight of solar panels and positioning them optimally to capture sunlight.

- Boat Docks & Marinas -

Screw piles are utilised in the construction of boat docks and marinas, providing a secure and durable foundation for these waterfront structures. They offer the advantage of quick installation with minimal disturbance to the aquatic environment.

- Retaining Walls & Shoring -

Screw piles can be used to support retaining walls and shoring systems. They stabilise soil or structures, preventing erosion and ensuring the safety of excavation sites.

- Underpinning & Foundation Repairs -

In cases of foundation settlement or subsidence, screw piles can be used for underpinning and repairing existing structures. They help lift and stabilise the foundation, providing a cost-effective solution for addressing settlement issues.

- Renewable Energy Projects -

Screw piles are used in renewable energy projects, such as wind turbines and small-scale hydropower installations, to anchor and support the foundations of these structures.

- Pipeline & Utility Installations -

Screw piles are sometimes used in pipeline and utility projects to support pipe anchors, valve stations, and other infrastructure components.

- Agricultural Applications -

In agricultural settings, screw piles are used for anchoring grain bins, storage facilities, and other agricultural structures.

- Erosion Control -

Screw piles can be used in erosion control applications, such as stabilising slopes and preventing soil erosion in sensitive environmental areas.

Screw Piles & their Merits:

Here are some of the key advantages of using screw piles.

- Rapid Installation:

One of the most significant advantages of screw piles is their quick and efficient installation. They can be installed rapidly, leading to time and cost savings in construction projects. There is no need for curing time as with concrete foundations.

- Minimal Site Disturbance:

The installation of screw piles generates minimal disturbance to the surrounding site. Unlike traditional foundation systems that require excavation and soil removal, screw piles are threaded into the ground, causing minimal disruption to the landscape and reducing the impact on the environment.

- Environmentally Friendly :

Screw piles are considered an environmentally friendly foundation solution because they do not involve the use of concrete or other materials that may have a higher environmental footprint. This makes them suitable for projects in ecologically sensitive areas.

- Low Noise & Vibration :

The installation process of screw piles produces very little noise and vibration, which is advantageous for projects in urban areas or near sensitive structures. It minimises disruptions to nearby residents and structures.

- Suitable for Various Soil Conditions:

Screw piles are effective in a wide range of soil conditions, including soft, loose, cohesive, and even rocky soils. They can adapt to various geological conditions, making them versatile for different projects.

- Easy Installation :

Screw piles can be installed quickly and easily using specialised equipment. The installation process is relatively simple and does not require a lot of labour or heavy machinery.

- Versatility:

Screw piles are versatile and can be used in a wide range of soil and ground conditions, including sandy, clayey, and rocky soils. They are suitable for various applications, such as supporting buildings, decks, bridges, and other structures.

- Load-Bearing Capacity:

Screw piles can provide high load-bearing capacity, making them suitable for both light and heavy structures. They are often used in areas with challenging soil conditions.

- Immediate Load Transfer:

Once installed, screw piles can immediately support the intended load. There is no need to wait for concrete to cure, as is the case with traditional concrete foundations.

- Cost-Effective:

The overall cost of using screw piles can be lower than traditional foundation systems, particularly when considering the reduced labour and equipment costs. They can also save time during construction.

- Removability & Reusability:

Screw piles can be easily removed if necessary, which can be beneficial in temporary construction projects or for structures that may need to be relocated. Additionally, they can be reused in other projects.

- Predictable Performance:

Screw piles are engineered for specific load requirements, and their performance can be accurately predicted. This makes them a reliable choice for foundation solutions.

- Year-Round Installation:

Screw piles can be installed year-round, regardless of weather conditions, which can be advantageous in regions with challenging climates.

Screw Piles and their Disadvantages:

While screw piles offer various advantages, they also come with some potential disadvantages and limitations. Here are few that are listed below;

- Limited Depth:

Screw piles may not be suitable for projects that require very deep foundations. They are typically used for shallow to moderately deep foundations and may not be practical for extremely deep or high-rise structures.

- Unsuitable for Hard Rock:

Screw piles are not ideal for drilling through hard rock or solid bedrock. The helical plates may not be able to penetrate such materials, and alternative foundation methods may be necessary.

- Corrosion:

Screw piles are typically made of steel, which can be susceptible to corrosion over time. Proper coating or treatment of the steel is essential to ensure the long-term durability of the piles, especially in corrosive soil environments.

- Limited Lateral Load Capacity:

Screw piles are primarily designed to support vertical loads. Their lateral load capacity is limited compared to other foundation systems like driven piles or drilled shafts. For structures subjected to significant lateral forces, additional lateral support may be needed.

- Site Preparation:

The soil condition at the installation site can affect the ease of screw pile installation. Extremely dense or compacted soils can make installation more challenging and time-consuming.

- Initial Cost:

The initial cost of screw piles can be higher than other foundation methods, such as concrete footings or wooden piles. However, this cost difference may be offset by the savings in installation time and equipment.

- Limited DIY Installations:

While screw piles are relatively straightforward to install with the right equipment and expertise, they still require specialised machinery and knowledge. They are not well-suited for DIY projects.

- Environmental Impact:

While screw piles have a reduced environmental impact compared to some other foundation methods, there is still the potential for disturbing the soil and ecosystems in environmentally sensitive areas.

- Frost Heave:

In regions with cold climates, frost heave can affect the stability of screw piles. Proper design and insulation measures may be needed to prevent frost-related issues.

- Code & Permitting Requirements:

Local building codes and permitting requirements can vary, and some regions may have specific regulations related to the use of screw piles. It's essential to ensure compliance with these regulations.

6. Driven Piles

Driven piles are a type of deep foundation system used in civil engineering and construction to support structures when the upper layers of soil are not suitable for shallow foundations. These piles are driven or hammered into the ground, typically by mechanical equipment, to transfer the load from the structure to deeper, more stable soil or bedrock layers. Driven piles come in various materials and shapes, including concrete, steel, timber, or composite materials.

Key characteristics and components of driven piles include:

- Pile Materials

Driven piles can be made from different materials, depending on the specific project requirements. Common materials include concrete, steel, timber, and composite materials. The choice of material depends on factors such as load capacity, soil conditions, and environmental considerations.

- Pile Shape

Driven piles can have various shapes, including H-piles, I-piles, pipe piles, and square or rectangular piles. The shape is chosen based on load-bearing capacity, ease of installation, and site-specific conditions.

- Pile Length

The length of driven piles varies depending on the depth required to reach stable soil or bedrock. Piles may be relatively short for shallow foundations or very long for deep foundations.

- Pile Installation

Driven piles are installed by driving them into the ground using a pile driver, hydraulic hammer, or similar equipment. The impact force of the equipment forces the pile into the soil, displacing the soil and creating a fictional or end-bearing connection with the surrounding earth.

- Load Capacity

Driven piles are designed to bear vertical and, in some cases, lateral loads from the structure they support. The load capacity of a driven pile is determined by factors such as the type of pile material, pile dimensions, soil properties, and the depth to which it is driven.

- Pile Testing

After installation, driven piles may be tested to ensure they meet design specifications and can safely support the intended loads. Common tests include static load tests, dynamic load tests, and integrity testing.

Scenarios Where Driven Piles are Essential:

Here are some common scenarios where driven piles are essential in building foundation and construction.

- Buildings on Soft or Compressible Soils

When constructing buildings on soft or compressible soils like clay or silt, driven piles are often used to reach deeper, more stable soil or bedrock layers. This ensures that the structure's weight is adequately supported and that it does not settle or sink over time.

- Bridge Foundations

Bridge piers and abutments often require deep foundations because they carry heavy loads and are located over water or in areas with unfavourable soil conditions. Driven piles provide a reliable and efficient solution for supporting bridge structures.

- Industrial Facilities

Large industrial facilities, such as factories and warehouses, may be constructed in areas with weak or loose soils. Driven piles are essential to provide the necessary load-bearing capacity to support heavy machinery and equipment.

- Marine Structures

Piles driven into the seabed or riverbed are essential for the construction of marine structures, such as docks, piers, and wharves. These piles provide stability and support for the structure and ensure it can withstand water forces and vessel loads.

- Offshore Platforms

In offshore oil and gas exploration, driven piles are used as foundation elements for offshore platforms. These piles must be driven deep into the seabed to ensure the stability and safety of the platform.

- Tall & Heavy Structures

Tall buildings, transmission towers, and other structures with significant vertical and lateral loads may require deep foundations to ensure stability. Driven piles can be essential in these cases to transfer the loads to suitable load-bearing layers.

- Urban Environments

In urban areas where space is limited and excavation is challenging, driven piles are a practical choice for foundation systems. They minimise soil disturbance and allow for the construction of deep foundations without extensive excavation.

- Environmental Constraints

In environmentally sensitive areas where excavation and soil disturbance should be minimised, driven piles offer a more eco-friendly foundation solution. This is especially important in regions with protected ecosystems or areas near water bodies.

- Temporary Structures

For temporary structures, such as event staging, temporary bridges, or construction sites with limited duration, driven piles can be an efficient and cost-effective foundation solution. They are easier to remove and reuse when the project is complete.

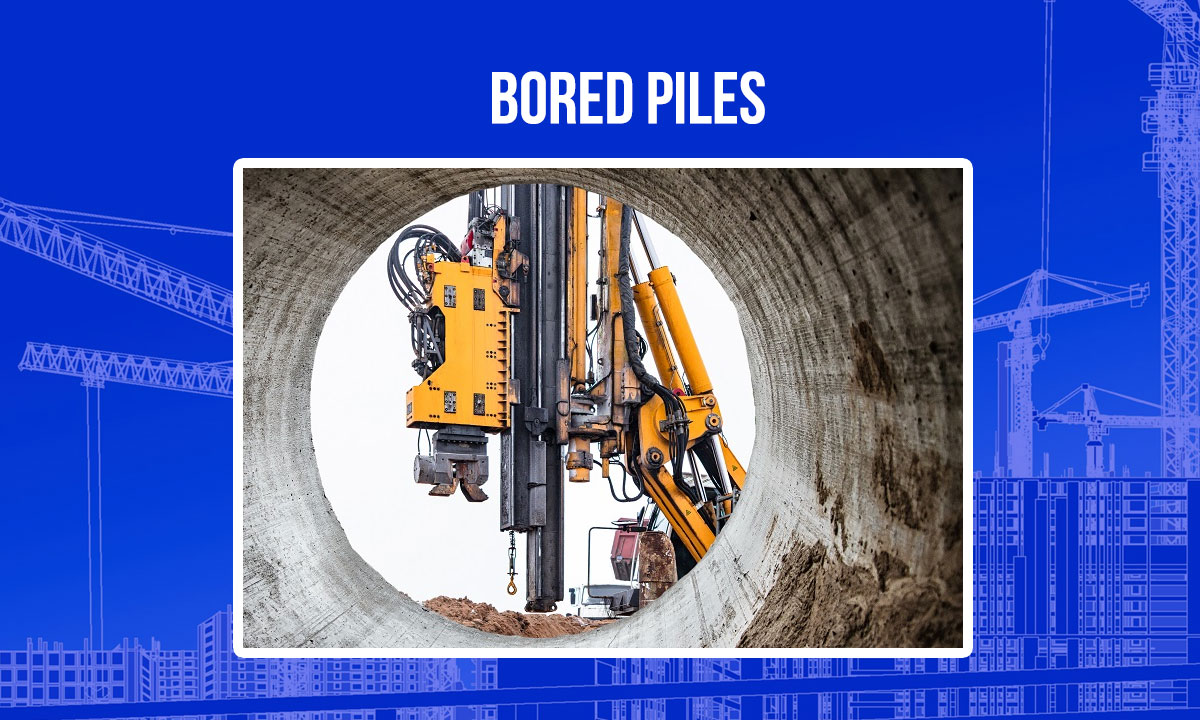

7. Bored Piles

Bored piles, also known as drilled shafts or auger-cast piles, are a type of foundation element used in civil engineering and construction. They are deep foundation elements designed to support heavy vertical loads, such as those from buildings, bridges, and other structures. Bored piles are typically used when shallow foundations, such as spread footings, are inadequate for the given soil conditions or when the construction site has limited space.

Bored piles have certain key features that are listed below;

- Drilling - Bored piles are created by drilling a hole into the ground using specialised drilling equipment. The hole can be excavated using various methods, including the use of a large-diameter auger, a drilling bucket, or other drilling tools. The diameter and depth of the pile are determined by the structural and geotechnical requirements of the project.

- Reinforcement - After the hole is drilled, a steel reinforcement cage is typically inserted into the borehole. The cage is designed to provide structural strength to the pile and is often made of steel bars or steel cages.

- Concrete Placement - Once the reinforcement cage is in place, concrete is poured into the borehole. The concrete is often of high quality and may be specially designed to meet the project's structural requirements. The concrete is typically pumped into the borehole to ensure a consistent and homogenous pile.

- Curing - The concrete is allowed to cure and harden within the bored hole. The curing process is crucial to achieving the desired strength of the pile.

- Cutting - After the concrete has fully cured, the top of the pile is often cut or trimmed to the required elevation, and any excess reinforcement is removed.

Bored Piles and their Advantages:

- Load-Bearing Capacity - Bored piles are designed to support heavy vertical loads. They can be constructed to reach great depths, which allows them to transfer the structural loads to more stable soil or rock layers beneath the ground, making them suitable for high-rise buildings and other large structures.

- Suitable for Challenging Soil Conditions - Bored piles can be used in various soil and rock conditions, including soft or loose soils, clay, silt, and dense or hard formations. Their versatility makes them a reliable choice in areas with variable or difficult ground conditions.

- Minimal Environmental Impact: Bored pile construction typically generates less noise and vibration compared to other deep foundation methods like driven piles. This makes them more environmentally friendly and suitable for use in urban areas or locations with sensitive surroundings.

- Large Diameter Options: Bored piles can be constructed in a wide range of diameters, allowing engineers to tailor the pile's size to meet the specific load requirements of the project.

- Precise Location and Verticality: Bored piles can be drilled with precision, ensuring accurate placement and vertical alignment. This is especially important in situations where precise positioning is required, such as for bridge piers or tower foundations.

- Reduced Risk of Pile Damage: Bored piles are less susceptible to damage during installation compared to driven piles, which can experience damage to their structural integrity when subjected to impact forces during driving.

- Enhanced Corrosion Resistance: Bored piles are often reinforced with steel cages that can be designed to resist corrosion, increasing their durability and long-term performance.

- Suitable for Various Structural Types: Bored piles can be used to support a wide range of structures, including buildings, bridges, industrial facilities, and offshore structures.

- Reduced Risk of Soil Displacement: Bored piles minimise the risk of soil displacement, making them a safe option for urban areas with existing structures or utilities.

8. Micro Piles

Micro piles, also known as micropiles or mini piles, are a specialised type of deep foundation element used in civil engineering and construction. These small-diameter piles are typically employed to support structures in areas with challenging soil conditions, limited access, or when traditional, larger-diameter piles are not feasible. Micro piles offer a versatile and effective solution for a wide range of construction projects. Here are some key characteristics and applications of micro piles:

- Small Diameter: Micro piles are typically much smaller in diameter compared to conventional bored piles or driven piles. They typically have diameters ranging from 3 to 12 inches (75 to 300 millimetres).

- High Load Capacity: Despite their small size, micro piles can be designed to carry significant vertical loads, making them suitable for a variety of structures, including buildings, bridges, and retaining walls.

- Versatile Installation Methods: Micro piles can be installed using various methods, including drilling, grouting, and driving. The choice of installation method depends on the specific project requirements and site conditions.

- Reinforcement: Micro piles are typically reinforced with steel bars or a steel casing to provide the necessary load-bearing capacity and structural integrity.

- Grouting: After the micro pile is installed, it is often grouted to enhance its load-carrying capacity and improve its bond with the surrounding soil or rock. This grouting can be performed under pressure, which is known as pressure grouting.

- Limited Access: Micro piles are ideal for sites with limited access, as their small diameter and versatile installation methods allow for construction in tight spaces or areas with difficult access, such as urban environments or steep slopes.

- Challenging Soil Conditions: Micro piles are effective in areas with poor or unstable soil conditions, including loose soils, sands, and fill materials. They can also be used in regions with seismic activity or in situations where liquefaction may occur.

- Retaining Structures: Micro piles are often used in retaining wall applications, stabilising slopes, and preventing landslides, as they can be installed in confined spaces close to existing structures.

- Retrofitting: Micro piles are suitable for retrofitting or strengthening existing foundations and structures, helping to improve their load-bearing capacity and stability.

- Reduced Vibration and Noise: The installation of micro piles typically generates less vibration and noise compared to larger foundation methods like driven piles, making them a preferred choice for projects in urban areas.

Micro Piles and Advantages:

- Versatility: Micro piles can be used in a wide range of ground conditions, including urban environments with limited access, rocky terrain, and areas with high groundwater tables. They are particularly useful in locations where traditional deep foundation methods, such as driven piles or drilled shafts, are impractical.

- Minimal Environmental Impact: Micro piles generate less noise, vibration, and disturbance compared to other foundation methods, making them more suitable for projects in urban or sensitive environments.

- High Load Capacity: Despite their small size, micro piles can carry significant structural loads. This is achieved through a combination of drilling techniques, reinforcement materials, and grouting procedures that enhance their load-bearing capacity.

- Retrofitting Existing Structures: Micro piles are ideal for underpinning or retrofitting existing buildings or structures. They can be installed in confined spaces to strengthen foundations or support additional loads, extending the lifespan of ageing structures.

- Rapid Installation: Micro piles can be installed relatively quickly, which can be especially advantageous for projects with tight schedules. They can also be installed in areas with restricted access, which may not be suitable for larger equipment.

- Tension and Compression Resistance: Micro piles can be designed to withstand both tension and compression loads, making them versatile for various applications, such as supporting buildings, bridges, retaining walls, and other structures.

- High Quality Control: The construction of micro piles is more easily monitored and controlled due to their smaller size and specialised drilling and grouting processes, which results in a consistent and reliable foundation system.

- Cost-Effective: While micro piles may have a higher initial cost per linear foot compared to other foundation methods, they often prove to be cost-effective in situations where access and site constraints make other options impractical.

Micro Piles and Demerits:

- Limited Load Capacity: Micro piles may have a lower load-bearing capacity compared to larger deep foundation systems like driven piles or drilled shafts. The smaller diameter of micro piles restricts the amount of reinforcement that can be added, which can limit their use in projects with very heavy loads.

- Limited Depth: Micro piles are typically used for relatively shallow to moderate depths, and they may not be suitable for very deep foundations. In situations where significant depth is required, other foundation methods may be more appropriate.

- Site-Specific Considerations: Micro piles are highly dependent on site-specific conditions, including soil and rock properties. Site investigations are crucial for designing and installing micro piles effectively. Unsuitable ground conditions can pose challenges or limit their effectiveness.

- Installation Complexity: The installation of micro piles involves specialised drilling equipment and grouting procedures, which can be more complex and time-consuming than traditional foundation methods. This complexity can lead to increased project costs.

- Maintenance and Inspection: Micro piles, like any foundation system, require ongoing maintenance and inspection to ensure their structural integrity. Accessing and inspecting the piles, especially in congested urban environments, can be challenging and costly.

- Limited Applicability: Micro piles may not be suitable for all types of structures and applications. They are more commonly used for smaller to medium-sized buildings, and their use may be limited in very large or heavy industrial applications.

- Environmental Considerations: While micro piles have a smaller environmental impact compared to some other foundation systems, the drilling process and use of grout materials can still have environmental consequences, such as groundwater contamination, which must be managed properly.

- Compatibility with Adjacent Structures: In situations where micro piles are used for underpinning or retrofitting existing structures, compatibility with the existing foundation and structure needs to be carefully considered to avoid potential issues during construction and afterward.

Different soil types have a significant impact on the performance and design of pile foundations. Pile foundations are used to transfer structural loads from a building or structure to deeper, more stable soil or rock layers. The choice of pile type, size, and design parameters is heavily influenced by the characteristics of the soil at the construction site. Here is how different soil types impact pile foundation.

Cohesive Soils (Clay):

- Cohesive soils like clay have fine particles that tend to stick together, making them susceptible to swelling when wet and shrinking when dry.

- Piles in clay soils may experience heave (upward movement) during wet periods and settlement during dry periods. This cyclic movement can lead to structural issues.

- Piles in clay soils often require additional lateral support, such as friction piles, to resist lateral loads.

Cohesionless Soils ( Sands & Gravels)

- Cohesionless soils like sands and gravels have larger, non-cohesive particles that allow water to drain more freely.

- Piles in sands generally perform well since they offer good bearing capacity and minimal settlement.

Silty Soils

- Silty soils contain a mix of fine and coarse particles and can exhibit both cohesive and cohesionless behaviour.

- The design of pile foundations in silty soils may need to consider the potential for settlement and lateral loads, depending on the specific composition of the soil.

Peat and Organic Soils

- Peat and organic soils consist of decomposed plant matter and have very low bearing capacity.

- Pile foundations in peat and organic soils often require significant lengths and are prone to settlement, so careful design is crucial.

Loose or Loose to Medium-Dense Sands and Gravels

- Loose soils have poor compaction and can lead to excessive settlement under structural loads.

- The design of pile foundations in loose soils may involve driving piles to considerable depths to reach denser, load-bearing strata.

Rock

- When bedrock is encountered relatively close to the surface, it may be an excellent option for pile foundations, as rock provides high bearing capacity and stability.

- However, drilling and installing piles in rock can be more challenging and costly than in soil.

Summarise the importance of selecting the right pile foundation for construction projects.

Selecting the right pile foundation for construction projects is crucial for the following reasons.