Brick vs. Cement Blocks in Masonry

Now let us have a quick comparison between bricks and concrete blocks in masonry as represented in the table below:

Bricks |

Concrete Blocks |

|---|---|

| Bricks kilns emit harmful toxins like sulphur & carbon monoxide that can be hazardous to health. | Concrete blocks are totally safe and environment friendly. They do not use soil and are sustainable. |

| Structures made out of bricks are not soundproof. | Structures made of concrete blocks are soundproof. They absorb the sound and hence prevent noise pollution. |

| Bricks are quite expensive. | Concrete blocks are cost-effective. |

| Bricks are brittle and may break down easily. | Concrete blocks are strong and less brittle. |

| Bricks can give an aesthetic look to home. | Concrete blocks may not give an aesthetic look for the homes. |

| Their size is relatively smaller. | They are large in size. |

| Brick kilns are less durable. | Concrete blocks are sturdy and more durable. |

| Bricks cannot withstand all weather conditions. | Concrete blocks are weather resistant. |

| Bricks are not thermal conductive. | Concrete blocks are thermal conductive. |

| Bricks have low tensile strength. | Concrete blocks have high tensile strength. |

| Bricks are primarily used for designs like structures, arches, curves, and extensions. | Concrete blocks are most often used in large infrastructure developments besides building homes. |

| Bricks are off standard size. | Concrete blocks come with various sizes, types and dimensions. |

This Article Contains

- Concrete Blocks in brief: What are they?

- Types of Concrete Blocks:

- Solid Concrete Blocks

- Hollow Concrete Blocks

- Concrete Stretcher Blocks

- Concrete Corner Blocks

- Lintel Blocks

- Concrete Pillar Blocks

- Partition concrete blocks

- Jamb Concrete Blocks

- Bullnose Concrete Block

- Frogged Concrete Blocks

- Paving Blocks

- Light Aerated Concrete Blocks

- Fly Ash Blocks

- Cellular Lightweight Concrete Blocks

- Concrete Blocks and Uses

- Concrete Blocks and its Merits

- Concrete Blocks and its Demerits

- 5 Things to Consider when You Buy Concrete Blocks

- Fire Resistant

- Design

- Insulation

- Acoustic Properties

- Structural Properties

- Brief Intro and History

- Bricks and its Strength

- How is Red Brick Manufactured

- Red Brick and its Average Size

- Testing of Red Brick

- Red Brick Types

- Red Bricks Dimensions

- Merits of Red Bricks

- Demerits of Red Bricks

- Red Bricks and its Uses

- Red Bricks and their Usage in Bengaluru

- Red Bricks Prices in Bangalore

- Conclusion

Concrete Blocks in brief: What are they?

Masonry construction is undergoing a fast change in recent times. Red bricks are getting replaced by concrete blocks in many residential homes. To put in simple terms, ‘Concrete blocks’ are building blocks that are composed entirely of concrete (cement, aggregate, water) and are then mortared together to make an impressive long-lasting structure. Concrete blocks are also widely used for the construction of filler walls and boundary walls. They are available in 3 types like solid, hollow, and cellular. To make block work faster, concrete blocks are made in large sizes so that they consume less cement. Concrete blocks are termed as ‘hollow blocks’ when the percentage of the voids is more than 25%. On the other hand, if the percentage of the voids is less than 25% they are known as perforated blocks. In concrete blocks, the cement aggregate ratio is 1:6.

Types of Concrete Blocks:

Solid Concrete Blocks

These are solid blocks formed by aggregate and utilized in construction projects. Solid concrete blocks are generally heavyweight in structure and are ideally used for large-scale projects like force-bearing walls. These blocks are almost equivalent to the size of the large red-sized bricks. As a result, building concrete masonry takes less time than brick masonry.

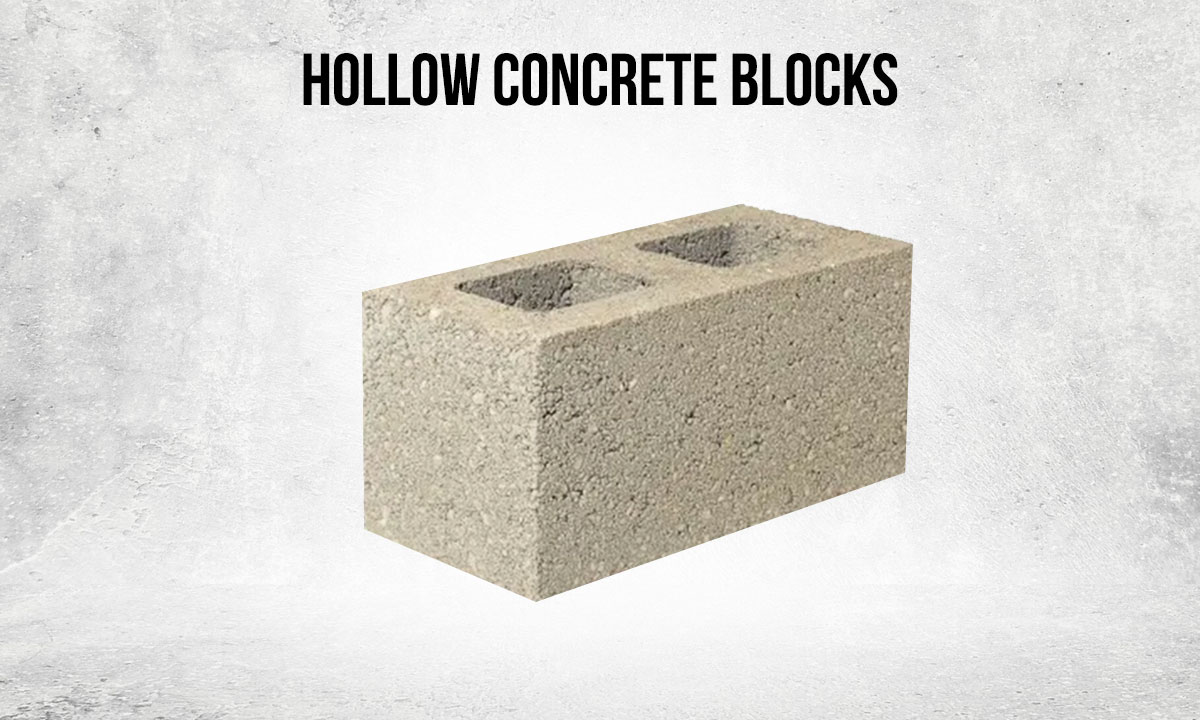

Hollow Concrete Blocks

Hollow concrete blocks are widely applied into use in masonry construction on a large scale. These hollow based concrete blocks speed-up the construction process and help save on cement and steel. Also at the same time, it reduces the cost of the labour on the job site. Hollow concrete blocks improve the physical wall qualities like noise reduction and thermal insulation. Besides, they also reduce the natural weight of masonry structure.

Hollow concrete blocks come in numerous designs, shapes, and sizes. Let us now discuss each one in detail.

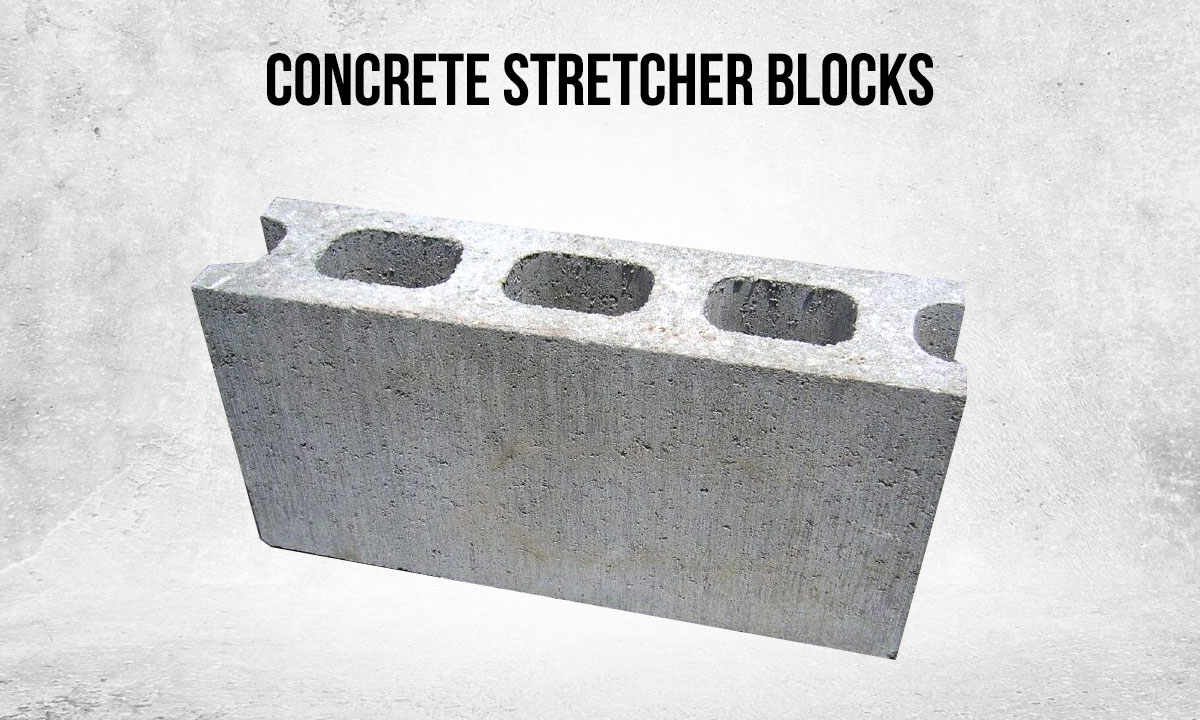

Concrete Stretcher Blocks

Concrete stretcher blocks are highly used in building projects. Concrete stretcher blocks usually use hollow concrete blocks. Since these blocks are durable and long-lasting, they are mostly used in large-scale building projects. The concrete stretcher blocks are applied parallel to each other.

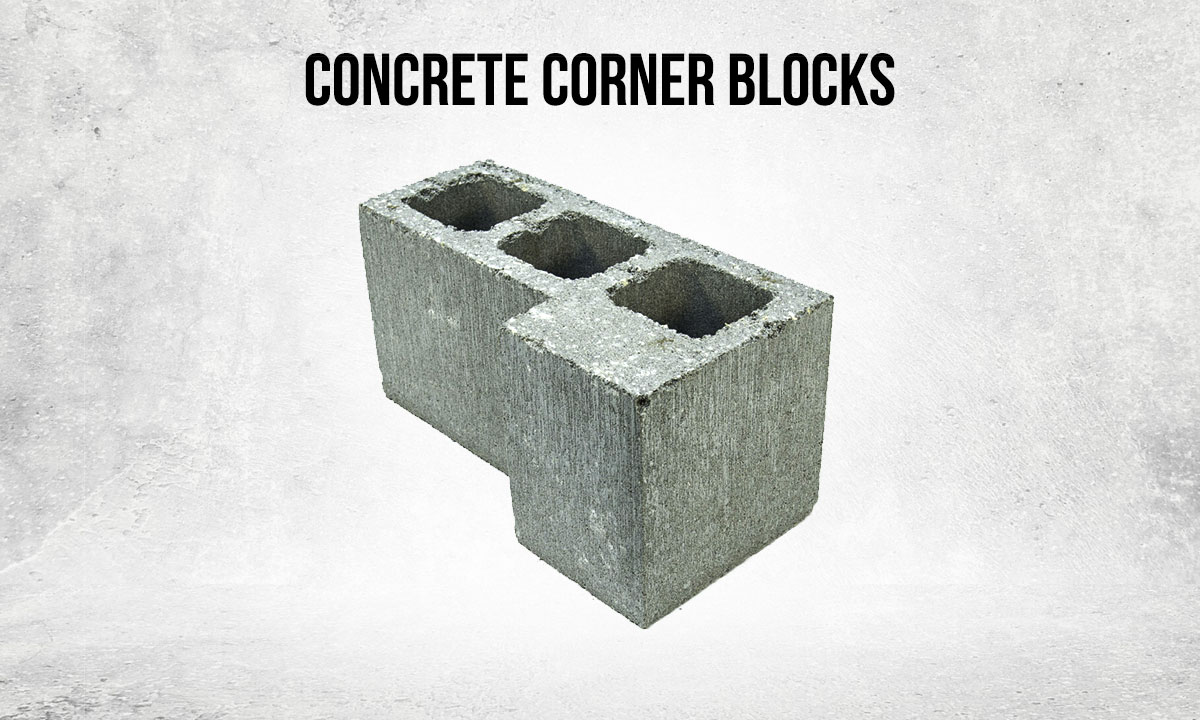

Concrete Corner Blocks

As the name says, these blocks are extensively used in the corners of window ends and doors in housing projects. The main characteristic of this block is that one corner block has a stretcher design, while the other remains plain. These blocks are placed in such a manner that one end of the plane is exposed to the exterior end and secured with the Stretcher block.

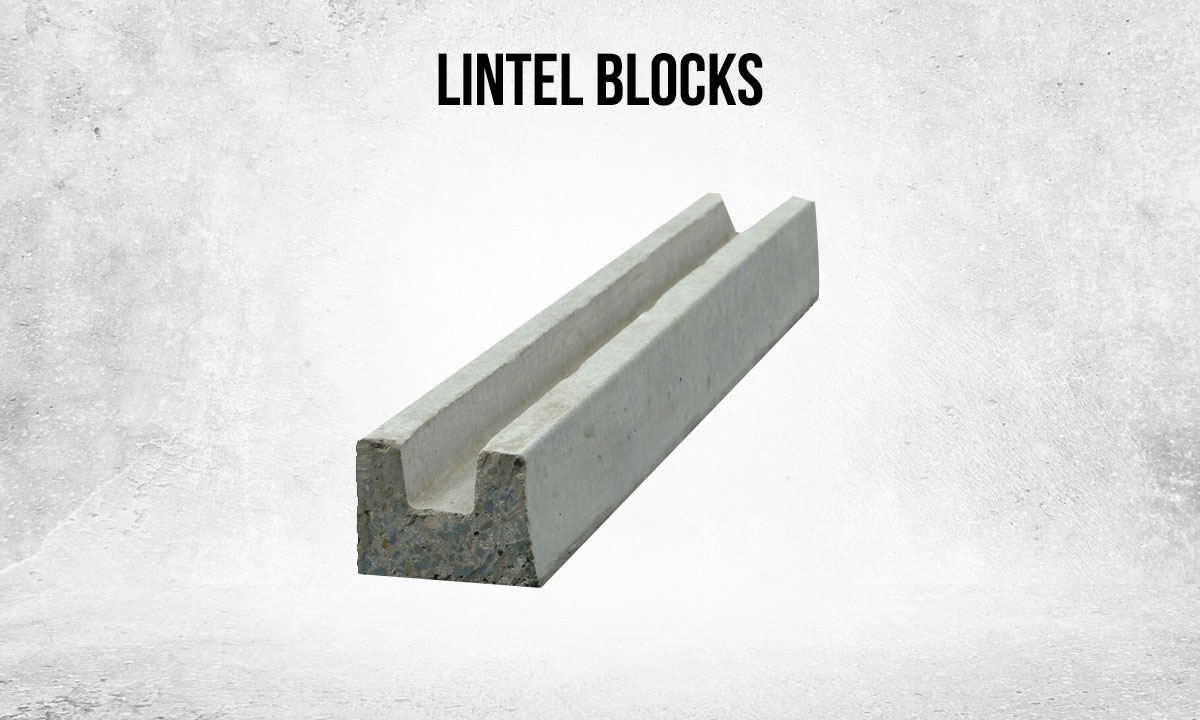

Lintel Blocks

Lintel blocks are prefabricated and made of prestressed concrete. The blocks are joined together to form lintel beams. The beams render structural support to the walls on both entry sides by distributing the loads from above the beams.

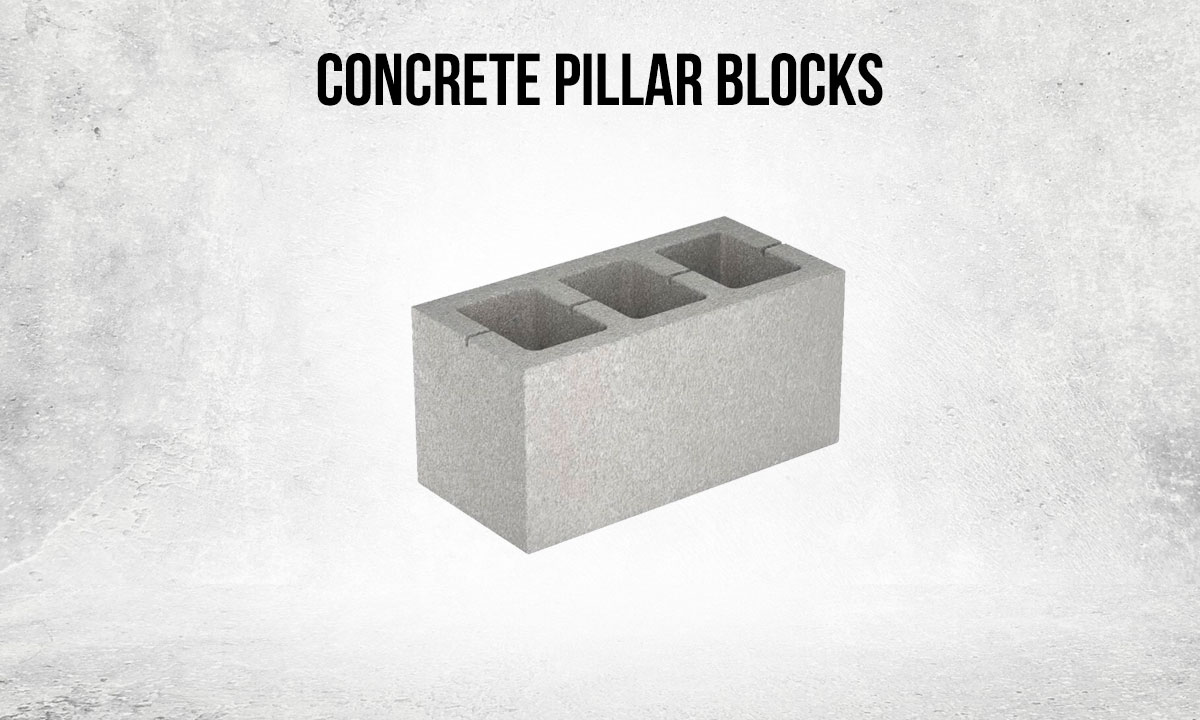

Concrete Pillar Blocks

As the name rightly says, concrete pillar blocks are commonly used in pillars, piers, girders and so on. They are also known as double corner blocks since both the corners are plain. Concrete pillar blocks are applied when the two corners are visible.

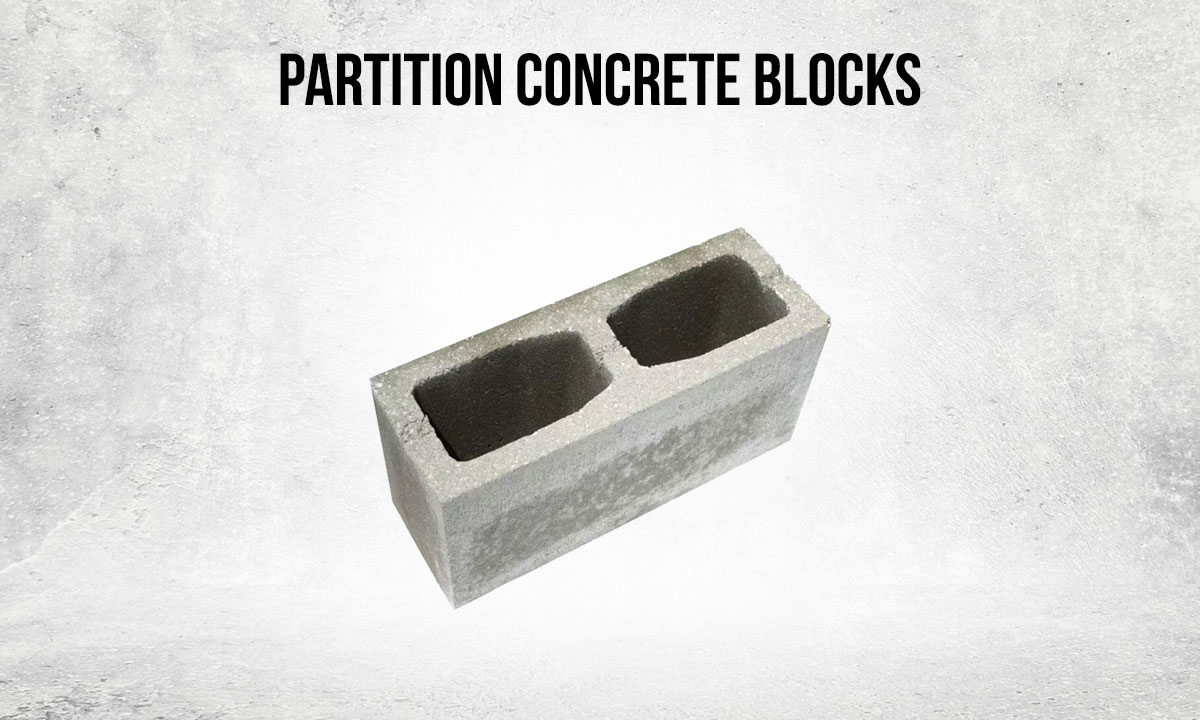

Partition concrete blocks

These concrete blocks are ideal for constructing partition walls. The blocks are almost similar to that of concrete pillar blocks. The only difference being the height of the partition concrete block is more than its breadth. Moreover, the partition concrete blocks hollow section is divided into 2 or 3 parts.

Jamb Concrete Blocks

Jamb concrete blocks are utilized for complex window openings in the wall. The jamb concrete blocks are further attached with stretchers and corner blocks. Its utility lies in providing space for the window casing parts when double huge windows are installed.

Bullnose Concrete Block

Bullnose concrete blocks and concrete pillar blocks are one at the same. The only difference between the two is that a bullnose concrete block comes with rounded corners. These blocks are best suited if one desires to have rounded edges.

Frogged Concrete Blocks

One of the unique features of this concrete block is that it assists in the retention of mortar and forms a strong bond with another block. The upper portion of the block has a frog section along with the header and stretcher.

Paving Blocks

They are reinforced concrete blocks which are rectangular or square in shape. Paving blocks are used for decorative approaches in the pavements along the roadsides. They are also used to build car parks and walkways. Paving blocks are also used to build road dividers. Paving blocks should be brightly painted so that they are easily visible to drivers and motorists.

Light Aerated Concrete Blocks

As these concrete blocks are made using superior quality cement known as ‘Portland’ cement, they are light in weight. As a result, aerated concrete like sand, aggregates, and other materials are used to make them.

Fly Ash Blocks

They are commonly made from the waste products generated from coal combustion and residue of fly ash in thermal power plants. Fly ash blocks are normally light in weight and cost-effective too.

Cellular Lightweight Concrete Blocks:

The main feature of this concrete block is that they are durable and lightweight. Known for its high mechanical strength and low heat conductivity, cellular lightweight concrete blocks are one of the best in its class. Cellular concrete blocks consist of a combination of Portland cement, silica, lime, and other materials that make them super light in weight. They are also known as Low density cellular concrete.

Concrete Blocks and Uses:

Concrete blocks have multiple uses that are stated below:

- As they are quick and easy to install, they form a great option for partition walls. Moreover, the inclusion of steel reinforcement adds to the strength of the structure.

- Hollow concrete blocks are extensively used for interior and exterior load-bearing walls, partitions, panel walls, and boundary walls.

- Solid concrete blocks are the most preferred choice for chimneys and fireplace buildings. They also go well with non-load bearing walls and garden walls.

- Concrete blocks are also used in a variety of smaller landscaping projects such as outdoor seating, decorative screens, outdoor bars, flower beds, and much more.

- Concrete blocks provide the much needed protection for stored commodities from the effects of changing weather conditions.

Concrete Blocks and its Merits:

- Concrete blocks make the space look larger as it increases the carpet surface. Since they are narrow blocks, it reduces the thickness of the walls to a great extent.

- The vast sizes of the concrete blocks make the building structures more durable and stronger.

- Concrete blocks offer better thermal insulation to the structures.

- Concrete blocks are sound proof. Since they absorb sound, they act as sound barriers and protect the home interiors from noise pollution.

- Concrete blocks do not exhaust nature as they are environment friendly.

- As concrete blocks come in customized shapes and sizes, individual pieces can be produced allowing for a rapid building cycle turnaround.

- Unlike traditional bricks, concrete blocks have a consistent size that reduces the need for plaster making them more cost-effective. The mortar consumption rate is lower in concrete blocks than in traditional brick masonry construction.

- Concrete blocks are made using Fly Ash which is a byproduct of nuclear energy.

- Being nature friendly concrete blocks do not consume top soil in the creation and assembling.

- Concrete blocks are highly resistant as they can withstand extreme weather conditions.

- As the blocks are large in size or dimensions, it helps the builders to complete the infrastructure projects on time.

Concrete Blocks and its Demerits:

- Concrete blocks are quite expensive. As a result, the expenses incurred in building a home can be a costly affair.

- Some of the concrete blocks may need to be cut leading to significant wastage of blocks.

- Homes built using concrete blocks look less attractive from outside.

- Structures built with concrete blocks may result in water seepage over a period of time.

- Concrete blocks may not be compatible due to some regional preferences.

- Due to environmental benefits, doors and windows can easily detract.

- If the required materials are unavailable, it can lead to waste of time and money.

- Skilled and experienced labour is required in the production of concrete blocks.

- Concrete cement blocks are less dense as compared to bricks.

By now you must have been quite familiar with the types of bricks / cement blocks used, their utilities, features, merits, and demerits.

5 Things to Consider when You Buy Concrete Blocks

At first look, most of the concrete blocks look alike, but there are a number of considerations that one needs to make before you proceed to buy the concrete blocks.

Fire Resistant

The first and the foremost thing that one should consider before buying a concrete block for the building project is to ascertain how resistant the concrete block to fire. If you have no idea regarding this, then it is always better to consult an expert or buy the same from a reputed vendor. The fireproof properties of concrete blocks vary according to coverage area and unit type.

Design

Concrete blocks now come in a wide range of colours and textures. The design you select should be accordingly planned with the decision as to what type of blocks one needs to buy. Consult your architect when in doubt as they would suggest the best alternatives available that will suit your plan.

Insulation

The insulating property differs from manufacturer to manufacturer and depends on the density of the blocks. To determine the insulating property, manufacturers undertake thermal conductivity tests. They increase the heat-insulating properties of the blocks by reducing the concrete block density by volume and produce a lower-weight block. This is done by solid grouting the cells of the concrete blocks thereby enhancing the insulating properties.

Acoustic Properties

The acoustic properties depend on the form of construction, junctions, and connections between the blocks and the properties of the materials used during manufacture of the blocks. Following the instructions laid by the authorities significantly increases the acoustic properties within the building.

Structural Properties

Concrete blocks differ as per type, size, and shape, but their fundamental structural property remains the same. One needs to follow the Indian building Code of Conduct when installing structural properties. Inserting steel rods into the cells or solid grouting the cells make a significantly stronger concrete block.

Brief Intro and History:

When it comes to masonry, a brick is a type of block that is put into use to build walls, pavements, and other elements in masonry construction. In simple terms a ‘brick’ is nothing but a composition of dried clay. Bricks can be joined using mortar, adhesives, or by interlocking them.

Bricks have a very old history. Bricks are considered to be one of the oldest known materials dating back to 7000 BC. They were first discovered in southern Turkey and around Jericho thousand years back. The Mesopotamians discovered the fired brick way back between 5000 and 4500 BC. The inhabitants from South Asia constructed air-dried mud brick structures between 7000 and 3300 BC. The inhabitants belonging to the Indus valley cities of Mohenjo-Daro and Harappa came up with fired brick as early as 3000 BC.

The first and the foremost bricks that came into existence were sun dried that were made from mud. In the year 1612, the English colonies in North America founded the first bricks that were probably made in Virginia. The first brick kiln erected was in 1629 at Salem now in Massachusetts in the USA. A ‘Block’ is nothing but a rectangular building unit consisting of similar materials that is usually larger in size than a brick. With the onset of the Industrial Revolution, the production of bricks increased substantially over the years. Bricks were the most preferred options as building materials when compared to stone. The bright red brick was chosen for construction to make buildings more visible in England due to dense fog and to prevent mishaps. It was at this point of time when the red brick became more prominent.

The development of the infrastructure has gained momentum in the last few years. Bigger structures were dependent on conventional red bricks until the construction industry turned things around to meet the prerequisites. It drastically turned the tide and took a giant leap to head towards AAC blocks. A few years back, The National Green Tribunal issued guidelines to boycott the use of sand and the top layer of the soil to manufacture the bricks. As mentioned earlier, the use of the bricks have been in use for many centuries. As we all know the traditional approach of building the structure was using the bricks. However, the changes in technology have brought about new innovations and features in recent times.

Now let us see more in detail about red bricks, their uses, and features.

Bricks and its Strength:

Recollect your childhood days when you last saw those red bricks. Remember those days when the boys next door would stack the red bricks as a wicket while playing gully cricket. Yes, you read it right! As mentioned earlier in the post, brick is a rectangular type of block fired in a kiln or sun dried. They are made using natural clay and sand. Red bricks are mostly used for construction purposes. One of the prime features of red brick lies in its strength. Red bricks are considered to be very hard materials and have been used for centuries in the construction industry. Bricks provide the buildings with structural strength. They render support to the ceilings and floors without any reinforcement. Many structures and monuments have been built using the red brick and still they have survived as centuries have rolled by.

How is Red Brick Manufactured?

One must be very curious to know how red brick is manufactured. Isn’t it? There are 3 steps involved in manufacture of red brick namely mixture of clay, compaction of clay with the mold, and fired in a kiln. The composition include; 50% - 60% silica (sand), 20% - 30% alumina (clay), 2% - 3% lime, 6% & 7% iron oxide, and 1% magnesia. The resulting mixture is added with water to make it a soft mud. This forms a rectangular size block which is left in the sun to dry and later fired on the kiln to make it hard. The clay needs to be heated at a temperature at 895 degree centigrade to 995 degree centigrade such that the silica will fuse with the brick.

Red Brick and its Average Size:

The size of the brick has developed over the years. The standard size of red brick is 9” long, 4 ½” wide, and 3” thick.

Testing of Red Brick:

Here are the ways how one can conduct the testing of red brick. Take 2 bricks and bang them lightly together. This will give a ringing sound. Another method is by dropping the red bricks to the ground. (I am sure you won’t drop on your head) A hard brick will be brittle and strong and will break cleanly.

Red Brick Types:

There are different types of red bricks found that come in different qualities. One can find more than 15,000 variants of such products in the market. Red bricks of superior quality are labelled with M-150 for their robust performance. On the other hand, red bricks having a low quality are labelled with M-125.

Red Bricks Dimensions:

Red bricks are produced as per the standards specified. The size of the standard product is 65x120x250 mm.

Merits of Red Bricks:

- Red bricks are low in maintenance.

- They are easily demolishable.

- Red bricks are solid in nature.

- Red bricks are highly fire-resistant. When it comes to fire rating, they fare better than concrete blocks.

- Red bricks are sturdy and durable in nature.

- Red bricks are recyclable and reusable.

- Red bricks provide vital stability to the structure as they are dense in nature.

- Red bricks make a good choice for simple infrastructure due to its compressive features.

Demerits of Red Bricks:

- Red bricks cause heavy pollution. It causes breathing problems for those who are more exposed to it.

- They are delicate materials and hence require careful handling.

- If not exposed to air, red bricks cause fluorescence as it absorbs more water.

- Red bricks are tensile in nature. When an external force acts upon it, it might break down.

- Another drawback of red bricks is they have a rough surface with uneven platform.

- Last but not the least, Red bricks need periodic cleaning else it leads to the growth of moulds.

Red Bricks and its Uses:

Red bricks have several uses which are listed below as they form a versatile building material.

- Red bricks are mostly used for structural walls, exterior walls, and for interior walls.

- They act as a bearing and non-bearing sound proof partitions.

- Red bricks are highly used for making chimneys and fireplaces as they are fire-resistant.

- They are also widely used in porches and terraces.

- Red bricks are used to make outdoor steps and paved floors.

- Their application is extensively used in building swimming pools.

Red Bricks and their Usage in Bengaluru:

The ‘Garden City’ is witnessing a robust growth in construction activities. Many reputed builders, developers, and home owners are coming up with numerous housing projects in Bangalore. Due to this the demand for usage of red bricks has gone up extensively. Red bricks in Bangalore are widely used as a structural material for the building of structures, laying foundations, arches, payments and so on. Their usage also applies for aesthetic purposes like landscaping, facing works, and in several other architectural purposes.

Red Bricks Prices in Bangalore:

The prices of some of the most widely used red bricks in Bangalore are given in the table below;

|

Brand |

Price |

Features/ Usage |

|---|---|---|

|

Red clay brick |

Rs. 7/- |

Side walls |

|

MTB red brick |

Rs. 8.5/- |

Water resistant |

|

Rectangular red brick |

Rs. 5/- |

Partition walls |

|

SVB cole burned brick |

Rs. 10/- |

Fire resistant/ partition walls |

|

Rectangular clay red bricks |

Rs.6/- |

Side walls/ fire resistant, water resistant |

|

Hollow clay bricks |

Rs. 80/- |

Side walls/ water resistant |

Conclusion:

This blog post must have provided you with a sound knowledge about bricks and concrete blocks. If you have gone through the post, then you might have known that concrete blocks have an edge over bricks for sure. For all those who are environmentally conscious, homes made with concrete blocks make sense when it comes to living arrangements. Now, it’s up to you to decide which material you would prefer to construct your home. “THE BALL IS IN YOUR COURT”.

Sqft.Expert provides a safe construction for your home. Meet our experts for your assistance who understand your requirements. Our team of experts will suggest and recommend the best designs possible to make your dream home look the way you always wanted it to be.

You can also refer to some of our other articles of sump construction, Teak wood types, Standard room sizes in a house.